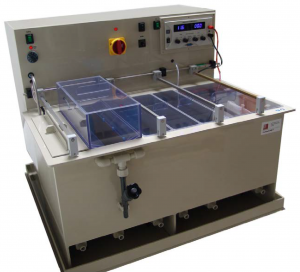

COMPACTA MD

COMPACTA TABLE UNIT

The creation of high-quality printed circuit boards and multilayers require high precision and systems engineering for the metallization of the holes, soldering of the contacts and finishing, which protects against oxidation and corrosion. To create the through-hole plated printed circuit boards, the PCBs must be pretreated by a wet chemical process, by metallizing the substrate inside the hole and therby establishing connection between the individual layers. For the through-hole plating galvanic process we offer our range COMPACTA, as a general-purpose electroplating plant, for the chemical or electrochemical treatment of metals in vertical technology. In consultation with the customers requirements the desired through-hole plating system is constructed.

The general production of high quality through-hole printed circuit boards, is based on an evironmentally friendly direct metallizing with graphit as catalyzer, in tenting or subtractive process.

The modular design of the systems provides the ability to integrate additional processes into the system concept: desmearing, blackening, tin stripping, resist stripping, immersion tin and organic protective coating (OSP), immersion nickel / gold, immersion silver, electroplated nickel / gold. The treatment and rinsing tanks are optimally fitted with high-quality facilities and system components which guarantee an optimal result for printed circuit board.